Renovation Slip Lining

Slip lining with an inserted pipe used for “renovation” purposes may utilize the same techniques as in “replacement slip lining” (where the methods are described more fully). The distinctions between the renovation and replacement categories depend on the extent to which the liner will function as a fully independent liner after installation as discussed in the descriptions for the “replacement” and “renovation” categories.

Also, included in the renovation slip lining category are techniques involving inserting a flexible hose to provide the pipe lining or to fulfill the operational function of the existing pipe to carry an internal flow. Such inserted hose linings may or may not be considered close-fit depending on the technique. Hose lining techniques only fall under the renovation method category since they do not attempt to replace all the structural and operational functions of the existing pipe.

Inserted Pipe

In this renovation application, a new pipe of smaller outside diameter than the inside diameter of the existing pipe is inserted (pushed or pulled) within the existing pipe. However, in contrast to replacement slip lining, the new pipe is not designed as a fully-independent lining. For a more complete description of the techniques used, please refer to the replacement section.

Continuous Pipe

See “replacement slip lining” for a general description of the method. Polyethylene (HDPE and PE) and polyvinyl chloride (PVC) pipes are most commonly used for continuous slip lining of circular, non-person entry pipes. The new pipe is laid out above ground and pulled through an excavated pit into the host pipe. The new pipe is winched through the host pipe to an exit pit or manhole. In situations where space for layout of the pipe above ground is limited, sections of the new PE or PVC pipe can be butt-fused during the installation process.

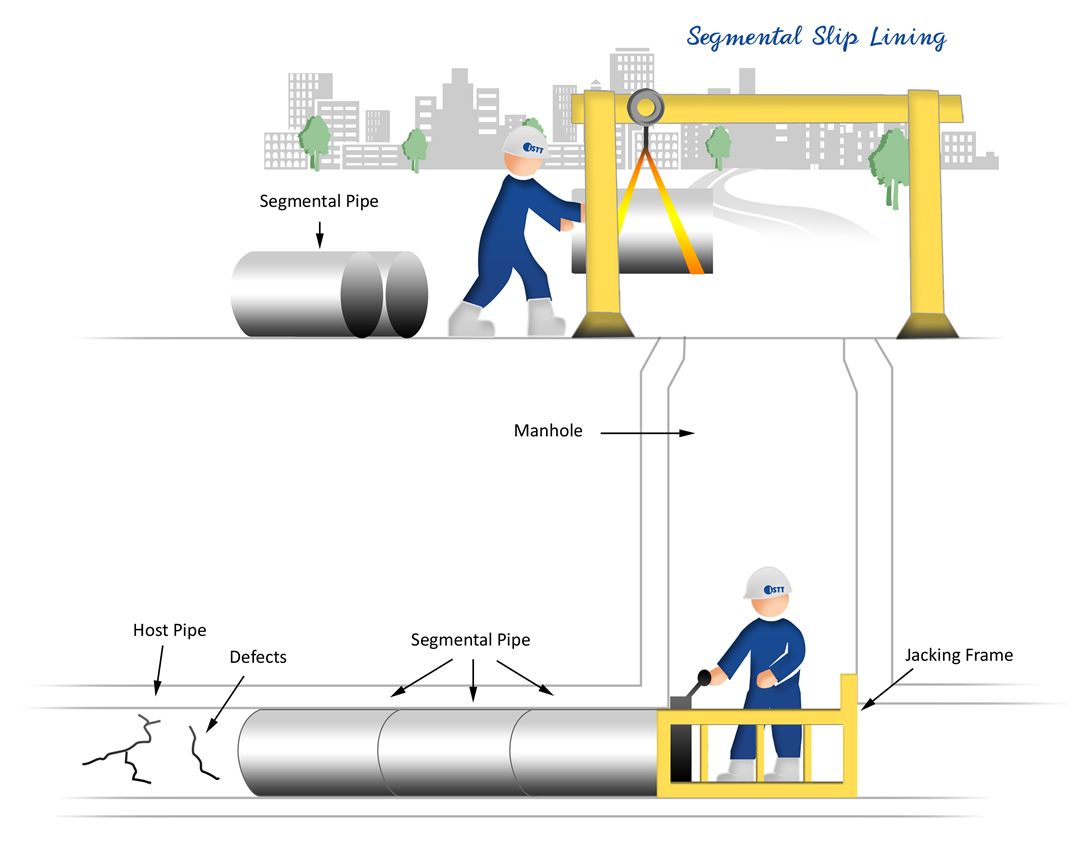

With Pipe Segments

See “replacement slip lining” for a general description of the method. In gravity sewer renovation applications, an important advantage of this form of slip lining is that the new pipe can be inserted in segments within the host pipe during active sewer flow – thus avoiding the need for bypass operations that may be necessary with other renovation techniques.

Segmental slip lining is typically used to insert Glass Reinforced Plastic (GRP) pipes into circular and non-circular pipes. The size of the host pipe can range from small non-man entry to larger man entry pipes. Segmental liners may be pushed into the host pipe by hydraulic power or winched in place. Concrete and steel pipe with higher compressive strength and stiffness may also be installed as slip liners and present fewer engineering challenges than plastic pipes during grouting.

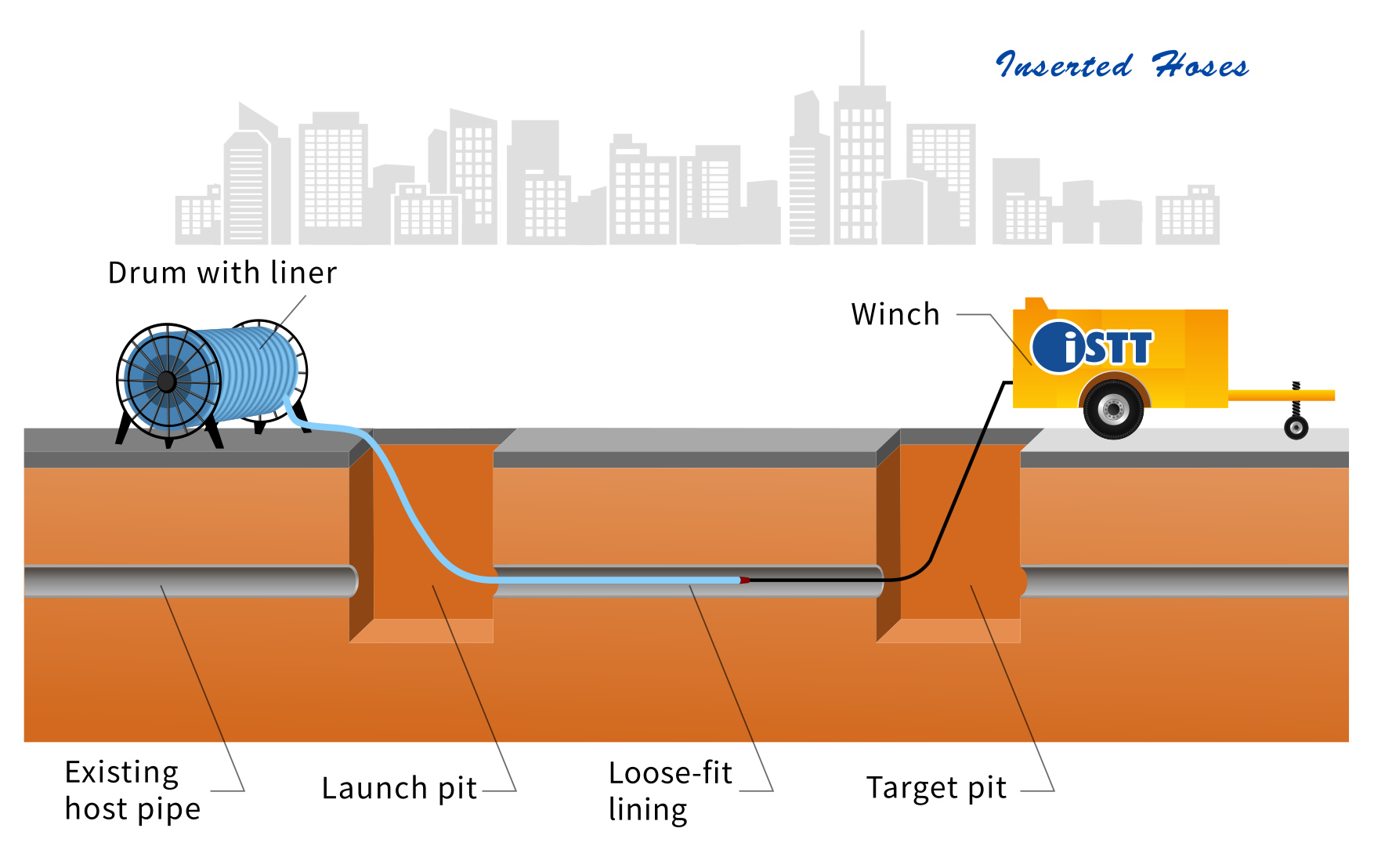

Inserted Hose

Inserted hoses or “hose linings” are linings that may be used to eliminate leakage in deteriorated pressure pipes. Typically, woven hose liners are flat fiber reinforced polyethylene hoses 150 to 500 mm in diameter. The hose is pulled into a host pipe and, once installed, the hose is inflated to conform to the walls of the pipe. Special fittings are used on the ends to secure the lining to the pipe. After installation, the flow is contained within the inner hose and can no longer leak through defects in the host pipe. The inner hose typically would be designed to resist the full interior pressure applied but could potentially be designed to rely partly on the structural support of the host pipe in resisting interior pressure (with the hose lining providing leak prevention). Hose linings are typically not designed to be able to resist external ground or groundwater pressures over the long-term and the host pipe is expected to continue to serve this function. Hose linings may laid loosely within the host pipe or be adhered to the host pipe during installation. In either case, consideration must be given to the situation when the pipe is depressurized temporarily – for maintenance or due to some unforeseen circumstance. If laid loose, the hose liner should be able to reinflate and displace any water accumulated within the annular space. If adhered, the adhesion should be considered sufficient to allow the liner to withstand the temporary depressurization.

Adhesive-backed hose

In this inserted hose lining variant, the inserted hose is adhered to the host pipe during installation. When the pipe is depressurized temporarily – for maintenance or due to some unforeseen circumstance – the adhesion should be considered sufficient to allow the liner to withstand the temporary depressurization. This hose lining technique forms a “close-fit” liner.

Non-adhered hose

In this inserted hose lining variant, the inserted hose is laid loosely within the host pipe. When the pipe is depressurized temporarily – for maintenance or due to some unforeseen circumstance – the hose liner is likely to deflate within the host pipe and it is necessary that it should be able to reinflate and displace any water accumulated within the annular space when the pressure is restored.